28.11.2018

The MERGE scientists use thermoplastic processes to produce the veneer prepregs, as the processing time is very short. Veneer produced from the regional wood species, European beech and spruce, is used. In the production process, the veneer is first pre-dried at approx. 80 degrees Celsius; it is then ready for the next step, so-called impregnation in which a thermoplastic matrix is plasticised. This matrix is used to wet the veneer. After it has been impregnated, the veneer is cooled under pressure at room temperature until it sets. The plastic forms a layer in the outer vessels of the veneer. However, what is decisive is that even in the composite, the veneer continues to have a low density inside.

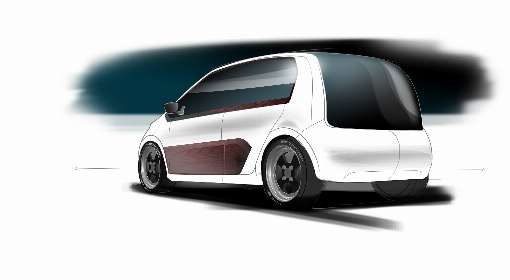

In the MERGE project, the veneer composites are also used practically, namely in the electrically driven lightweight “MERGE Up!” car, a model of the “Chemnitz Car Concepts” research project. In this car, they are used to make the covers for a functional input system in the car's centre console and as exterior components for the side door. While the component for the side door is made by shaping the pressed veneer prepreg, the veneer cover of the centre console fits into a newly developed hybrid laminate. By touching the functional area of the centre console made of veneer prepregs, instead of the usual pressing of a switch system or knobs, the driver can control individual electronic applications in the vehicle.

“The MERGE project has shown impressively that the renewable natural material veneer still has plenty of innovative potential. As fibre reinforcement in composite with other materials, it offers many new forward-looking potential applications”, said the Secretary of Initiative Furnier + Natur (IFN), Ursula Geismann. IFN/RK

Initiative Furnier + Natur (IFN)

Initiative Furnier + Natur (IFN) e.V. was founded in 1996 by the German veneer industry and its partners. The purpose of the association based in Bad Honnef is to promote veneer as a material. It is funded and supported by European companies in the veneer industry, trade and the veneer processing industry as well as professional associations of the timber industry.

Photo: Veneer prepregs are used in practice, for example, in the innovative electrically driven lightweight “MERGE Up!” car as external side door components, among other things. Photo: TU Chemnitz

Downloads

PM-2018-IFN-Chemnitz_Concept_ Car.jpg (0.6 MB)

Modern veneer prepregs: Innovative veneer use for the car of the future

Bad Honnef. Wood has a comparatively low density. The material is therefore ideally suitable - especially in the form of veneer - for use in lightweight construction. Scientists at TU Chemnitz and TU Dresden are currently undertaking research as part of the MERGE Federal Excellence Cluster to develop new lightweight construction materials made of veneer and plastic. “Many potential practical applications exist for wood (veneer)-plastic composites (so-called veneer prepregs), for example, in the automotive sector. They are cost-effective and, in addition to their good specific material properties, they are highly recyclable”, says Professor André Wagenführ of the Institut für Naturstofftechnik at TU Dresden.The MERGE scientists use thermoplastic processes to produce the veneer prepregs, as the processing time is very short. Veneer produced from the regional wood species, European beech and spruce, is used. In the production process, the veneer is first pre-dried at approx. 80 degrees Celsius; it is then ready for the next step, so-called impregnation in which a thermoplastic matrix is plasticised. This matrix is used to wet the veneer. After it has been impregnated, the veneer is cooled under pressure at room temperature until it sets. The plastic forms a layer in the outer vessels of the veneer. However, what is decisive is that even in the composite, the veneer continues to have a low density inside.

In the MERGE project, the veneer composites are also used practically, namely in the electrically driven lightweight “MERGE Up!” car, a model of the “Chemnitz Car Concepts” research project. In this car, they are used to make the covers for a functional input system in the car's centre console and as exterior components for the side door. While the component for the side door is made by shaping the pressed veneer prepreg, the veneer cover of the centre console fits into a newly developed hybrid laminate. By touching the functional area of the centre console made of veneer prepregs, instead of the usual pressing of a switch system or knobs, the driver can control individual electronic applications in the vehicle.

“The MERGE project has shown impressively that the renewable natural material veneer still has plenty of innovative potential. As fibre reinforcement in composite with other materials, it offers many new forward-looking potential applications”, said the Secretary of Initiative Furnier + Natur (IFN), Ursula Geismann. IFN/RK

Initiative Furnier + Natur (IFN)

Initiative Furnier + Natur (IFN) e.V. was founded in 1996 by the German veneer industry and its partners. The purpose of the association based in Bad Honnef is to promote veneer as a material. It is funded and supported by European companies in the veneer industry, trade and the veneer processing industry as well as professional associations of the timber industry.

Photo: Veneer prepregs are used in practice, for example, in the innovative electrically driven lightweight “MERGE Up!” car as external side door components, among other things. Photo: TU Chemnitz

Downloads

PM-2018-IFN-Chemnitz_Concept_ Car.jpg (0.6 MB)